Industrial Methods: What They Are and Why You Should Care

If you’ve ever clicked ‘Buy Now’ on a pharmacy site, you probably didn’t think about how the pill was actually made. The truth is that industrial methods – the processes factories use to turn raw chemicals into tablets, capsules, or liquids – have a big impact on what lands in your hands.

First off, industrial methods aren’t just fancy jargon. They cover everything from mixing and granulating powders to coating tablets so they dissolve at the right speed. A clean, well‑controlled process means consistent strength, fewer side effects, and lower chances of contamination.

Key Steps in Modern Drug Manufacturing

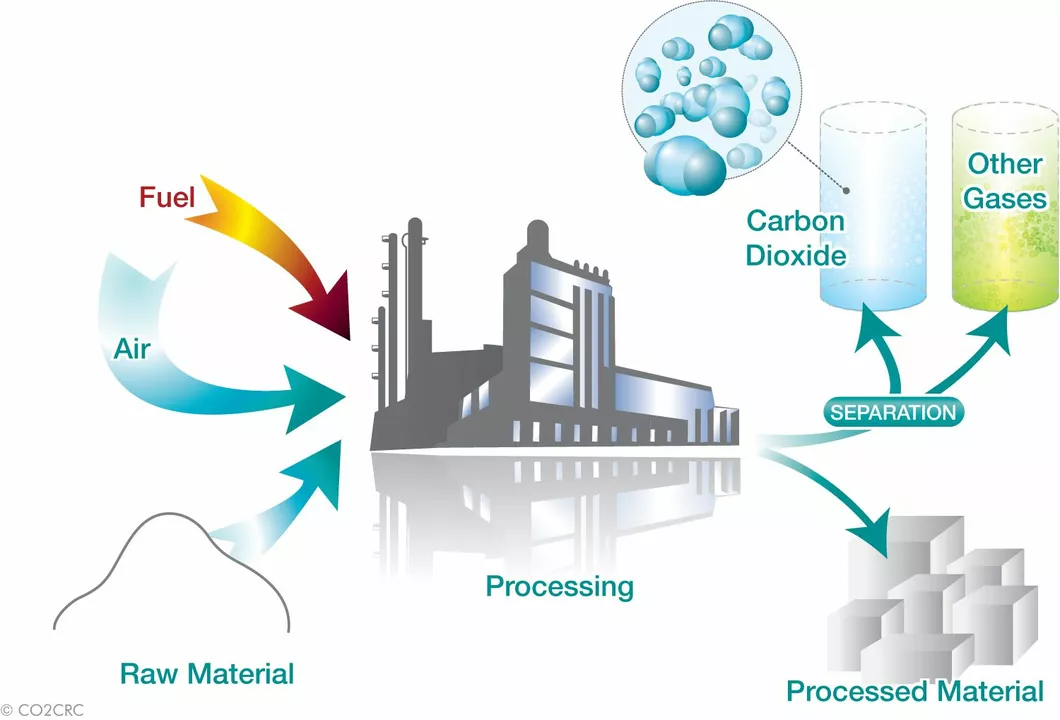

Most drugs go through three basic stages: synthesis, formulation, and finishing. During synthesis, chemists create the active ingredient in large reactors. Good industrial practices keep temperature, pressure, and timing exact – a slip can change how strong the medicine is.

The next stage, formulation, blends the active ingredient with fillers, binders, or liquids. Here, methods like wet granulation or direct compression decide whether a tablet will crush easily or dissolve too fast. Choosing the right method helps manufacturers meet dosage guidelines and keep costs down.Finally, finishing adds coatings or packs the product. Coatings protect the drug from moisture and control where it releases in your gut. A solid finish also protects against breakage during shipping – something online shoppers notice when pills arrive whole.

Why Industrial Methods Matter to Online Buyers

When you shop on sites like genericbucket.com or evo‑pharmacy.com, you’re trusting that the drugs were produced with proper industrial methods. Reputable online pharmacies usually source from manufacturers that follow GMP (Good Manufacturing Practice) guidelines. Those guidelines are a set of rules that make sure every batch meets quality standards.

If a manufacturer cuts corners – say, skips a filtration step or uses an outdated coating technique – the final product can be less effective or even harmful. That’s why you’ll see reviews mentioning “consistent dosage” or “no broken tablets.” Those comments often reflect solid industrial processes behind the scenes.

Another practical tip: check if the pharmacy lists batch numbers or manufacturing dates. When a company is transparent about its production, it usually means they’re confident in their methods.

Industrial methods also affect price. Efficient processes lower waste and energy use, which can translate into cheaper meds for you. Conversely, older, slower techniques often raise costs – something you might see reflected in higher prices for the same generic drug on different sites.

Bottom line: the way a drug is made shapes its safety, effectiveness, and price. When you pick an online pharmacy, look for clues about their manufacturers’ industrial methods – GMP certification, batch info, and clear sourcing details are good signs.

Understanding these basics helps you make smarter choices, avoid low‑quality meds, and get the best value for your health budget. So next time you order a prescription, remember that behind every pill is an industrial process working to keep you safe.

How calcium carbonate is produced synthetically

Calcium carbonate is a widely used compound, and its synthetic production is an interesting process. First, a reaction between calcium chloride and sodium carbonate takes place, which forms calcium carbonate as a precipitate. This is then filtered, washed, and dried to obtain a pure product. Another method involves reacting quicklime with water to create calcium hydroxide, which is then exposed to carbon dioxide gas to produce calcium carbonate. These processes allow for the creation of various forms of calcium carbonate, such as precipitated calcium carbonate (PCC) and ground calcium carbonate (GCC), which are useful in numerous applications.